Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Basic Info

| Model NO. | Truck Tire and Car Tire Recycling Plant |

| Type of General Rubber Machinery | Granulating Machine |

| Type of Tire Machinery | Rubber Regeneration Machinery |

| Transport Package | Film with Wooden Pallet |

| Specification | 300kg/H to 3000kg/H for Rubber Granula or Powder |

| Trademark | Genox |

| Origin | Guangzhou |

| HS Code | 84778000 |

| Production Capacity | as Requirement |

Product Description

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

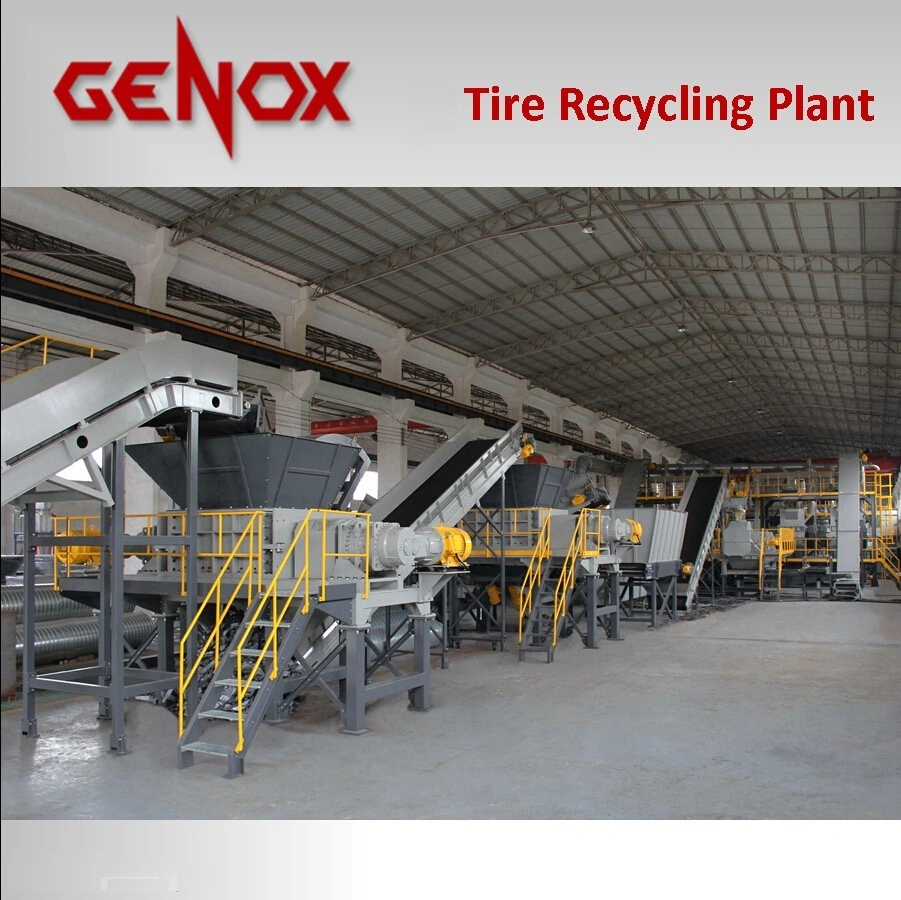

Product DescriptionTruck Tire and Car Tire Recycling PlantCar tires, truck tires and even consrtuction tires can be processed by GENOX high performance tire recycling plants 3,000-6,000kg per hour through without anymanual separation. Rubber, fluff and steel wires arefull-automatically separated by the system.The steel cleaner is available for cleaning the rubber stick on the steel.The ETS Plants are designed for recycling car and truck tires for the production of clean rubber crumb and the separation of steel and textiles. Using normal temperature and non-chemical processing technology, these recycling systems are cost effective and don't create secondary pollution. These plants are intended for customers who require an entry level, small scale tire recycling system with a capacity of 500-2,000kg/hr.A typical ETS tire recycling plant would include the following components: > Debeader - removal of the reinforcing steel wires from the tire rims> Infeed Conveyor Belt - enables easy, controlled feeding of the tires> Twin Shaft Shredder - shears the tires into strips > Conveyor Belt - transports the tire shred to the Rasper> Rasper - reduces the shred into 15-20mm chips and liberates remaining steel from the rubber > Overbelt Magnet - separation of liberated steel from the rubber chips> Conveyor Belt - transport the rubber chips> Granulator - size reduction of the chips to 1-4mm granules and liberates the textile fraction to allow separation> Vibratory Screen - sorts the granules by size and removes the majority of textile> Zig-Zag Classifier - removal of remaining textile> Drum magnet - removal of remaining steel fines> Big-Bag Station > Central De-dusting Unit - removes dust and fines from the system and filters the air before returning to atmosphere> Control Panel The correct combination and sizing of the above listed equipment will provide a reliable, efficient tire recycling system that will produce a high quality rubber granulate, clean textile and steel ideal for sale, or for use in further processing equipment. TestingPrior to delivery from our facility, all our tire recycling plants are set up and tested under "real world" conditions to ensure the plant capacity and quality of the finished products are guaranteed. Customers are welcomed and encouraged to attend these trials to see their plant in operation, receive training on the operation and maintenance of their system, and to see similar equipment in build. Detailed Photos

Company ProfileGenox is a combined word of "Generating Oxygen" with a meaning of creating a better environment through new and innovative technology.Both the employees and management of Genox abide by this principle and constantly pursue the most effective, reliable and cost-effective solutions for the recycling of waste materials. Through extensive testing, seeking feedback from our valued customers and distributors, and working closely with our European engineering partners. Genox has developed an extensive range of technically advanced machinery for the processing of plastics, tires, and E-waste. Plastics shredding, granulation, and washing systems, including complete recycling plants, are the important part of the Genox product range. Single shaft shredders, two shaft shredders, granulators, washing tanks, dewatering centrifuges and other necessary equipment which can be customized on request allows us to offer bespoke proposals tailored to suit the requirements of each and every customer.

FAQ

1.Question:Will we provide pre-sale services ?Answer:Genox consists of experienced specialists, we will offer a suitable solution according client's requirement in time.2.Question:Is our after-sales service excellent ?Answer:Genox's skilled technicians are available to assist with onsite installation,commissioning & training on request. This will enable customers to optimize the performance of their new plant. Customers will be briefed on all aspects relating to operation and maintenance by a Genox technician. Dimensional drawings together with service requirements will be provided prior to delivery of the equipment. This will allow the customer to prepare the site and allow them to commence production in a timely fashion.Genox holds a adequately inventory of spare parts and their efficient service personnel will ensure that any required part will be dispatched without delay. Delivery of the spare parts may be by air, sea or courier depending on the urgency of the situation. Customers are encouraged to hold their own critical spare parts such as granulator blades and screens to ensure optimal machine condition and performance. 3.Question:Will we provide technical support ?Answer:Genox provides enough hardware resource especially for large-scale production lines, clients can carry out installation, commissioning and acceptance before delivery.